CNC Turning is a subtractive process that removes material from a rotating cylindrical billet resulting in a symmetrical cross-section.

Jupai’s advanced CNC turning capabilities allow for a range of high precision CNC turning operations. Tolerances are tightly controlled and are available from +/- 0.01mm or better on request. Through many years of experience we have the expertise to deliver complex CNC turned parts. From parts a few millimetres in size, to large 1500mm long and 700mm diameter parts, you can chose Shenzhen Jupai Precision Product Co., Ltd.

From simple components to highly complex specifications, we select the best partner to produce your CNC turned parts based on your requirements and price.

Upload your design files for a fast quote, accurate lead times, and free DFM analysis.

*Please attach any format including STEP, STP, STL, IGS, IGES, PRT, SLDPRT, SAT, DWG, PDF, X_T, RAR.

– Applications: Valve bodies, drill bits, pump shafts, and pipeline connectors.

– Materials: Corrosion-resistant alloys (e.g., duplex stainless steel, Inconel) and hardened steel.

– Examples: Downhole tooling, pressure vessel fittings, and flange adapters.

– Applications: Turbine shafts, hydraulic fittings, missile components, and landing gear parts.

– Materials: Titanium (Ti-6Al-4V), Inconel (718/625), and high-strength aluminum alloys for extreme environments.

– Examples: Engine mounts, fasteners, and radar system housings.

– Applications: Bone screws, surgical tool handles, dental implants, and prosthetic joints.

– Materials: Biocompatible titanium, stainless steel (316L), and PEEK plastic.

– Examples: Custom spinal rods, syringe nozzles, and MRI machine components.

– Applications: Wind turbine shafts, solar panel brackets, and nuclear reactor coolant fittings.

– Materials: Stainless steel, copper alloys (for thermal conductivity), and carbon composites.

-Examples: Hydroelectric turbine blades and battery terminal connectors.

– Applications: Artillery shells, submarine valve systems, and radar antenna mounts.

– Materials: Marine-grade aluminum (5052/5083), super duplex stainless steel.

– Applications: Shafts, bushings, engine valves, pistons, brake system components (e.g., caliper pins), and transmission parts.

– Materials: Stainless steel (e.g., 304/316), aluminum alloys (6061/7075), and brass for wear-resistant or lightweight components.

– Examples: Precision fuel injectors, wheel hubs, and steering column parts.

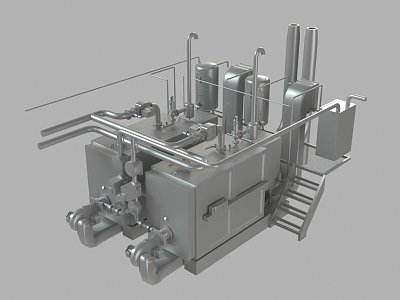

– Applications: Cylinder rods, valve spools, fluid couplings, and compressor rotors.

– Materials: Carbon steel (1045/4140), stainless steel, and bronze for high-pressure systems.

– Examples: Hydraulic pump shafts and pneumatic valve bodies.

-Key Advantages of CNC Turning:

– Ideal for rotationally symmetric parts (e.g., cylinders, cones).

– High precision (±0.001–0.005 mm) for tight-tolerance applications.

– Efficient for high-volume production of standardized components.

.png)

For specific machine references, brands like Haas ST Series, Mazak Quick Turn, and DMG MORI NLX lathes are widely used in these industries. Of course, Jupai owns all of these CNC equipment. If you have a high tolerance and high quality project requiring cnc machining, Jupai is confident that we can be one of your most trusted machined parts manufacturers in China.

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

The first article under $200 is free.( Background investigation required.)

At present, the automatic quotation of CNC is for reference only, and the actual discount is subject to manualcalculation. After submitting the inguiry, a professional customer service will communicate with you within 12 hours.

Best CNC Machined Parts Manufacturer and Factory in China.

Offer Fast and Cost-Effective One-Stop CNC Machining Services.