Upload your design files for a fast quote, accurate lead times, and free DFM analysis.

*Please attach any format including STEP, STP, STL, IGS, IGES, PRT, SLDPRT, SAT, DWG, PDF, X_T, RAR.

10+ Years of CNC Machining Expertise

500,000+ Precision Parts Produced Annually

150+ Advanced CNC Machines

10000+ Satisfled Clients Worldwide

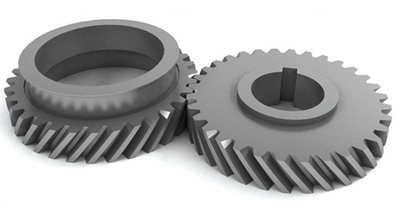

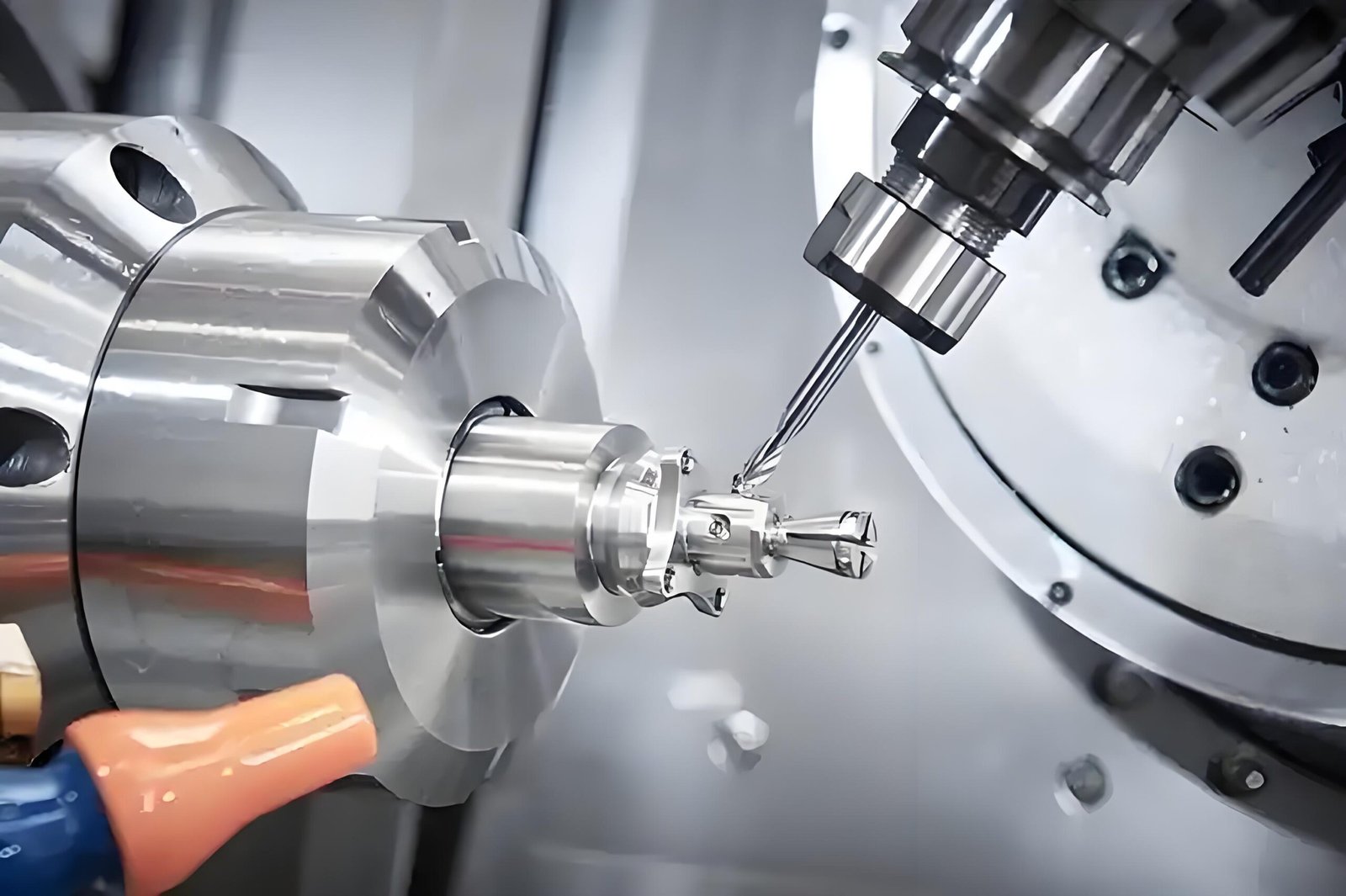

CNC Machining Services are Known for their Eficiency, Precision, and Affordability. As the top-rated CNC machining partsmanufacturer in China, make your customized CNC machined parts faster & easier. Jupai offers precision CNC machining services covering an incredible range of industries and applications. Check out some of our CNC machining part examples from our customers worldwide:

Due to its inherent characteristics, the oil and gas industry always requires highly rugged precision components that can withstand harsh working and external conditions.Jupai has recognized this and always pursues the demanding durability, resistance and reliability required in this field. With rich experience in working closely with the top oil and gas companies in the world, we have earned a good reputation for high levels of accuracy, precision and efficiency and are deeply trusted by our customers. We are happy to face and meet all challenges and are committed to manufacturing high-quality parts that can be used in the most challenging tasks.

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

As a qualified and reliable CNC machining company, JUPAI is equipped with advanced facilities to provide toplevel CNC manufacturing services, including the following

Jupai CNC milling machines excel at creating complex parts with multiple features. They can produce intricate contours, precise holes, and slots on various materials. With multi-axis capabilities, these machines offer versatility in creating both simple and complex 3D forms, ensuring high accuracy for prototyping and production runs.

3-, 4-, and 5-Axis CNC Machining

99+ Materials of Your Choice

Various Surface Finishes

Customized Machined Parts design

Tight Tolerances (down to ± 0.002mm)

At Jupai CNC, we specialize in high-precision lathe parts processing for industries that demand excellence. With state-of-the-art equipment, unmatched precision, and a commitment to quality, we deliver components that meet the most rigorous standards.

Multi-Axis CNC Lathes

High-Speed Turning Centers

Automated Systems

High Precision: ±0.002mm

Max. Size:2550*1200*800

Adhering to ISO Management standards, Jupai established a robust management system. Jupai prioritized customer satisfaction and continuous improvement. Our development strategy revolves around closely customers’needs.

ISO9001, ISO13485,IATF16949, GJB9100C

At Jupai CNC factory, quality control is the cornerstone of our operations. We are committed to delivering precision-engineered components that meet the highest industry standards with advanced testing equipment.

Hexagon&Leader CMM

2.5 CMM machine

Trimos Height Gauge

Overhead Projector

Rockwell Hardness Tester

Offer Fast and Cost-Effective One-Stop CNC Machining Services.

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

The first article under $200 is free.( Background investigation required.)

At present, the automatic quotation of CNC is for reference only, and the actual discount is subject to manualcalculation. After submitting the inguiry, a professional customer service will communicate with you within 12 hours.

Best CNC Machined Parts Manufacturer and Factory in China.

Offer Fast and Cost-Effective One-Stop CNC Machining Services.