CNC Milling is a subtractive manufacturing process that uses a drill-like cutting tool to remove material from a workpiece.

Multi Axis CNC Milling allows parts with muliple surfaces to be machined quickly and easily. Parts requiring good flatness and accurate complex curved surfaces can be produced easily.

CNC Milling is widely adopted for low to medium volume metal and plastic parts that require high strength and dimensional accuracy. CNC Milling is one of Jupai Machining Services Inc.’s core manufacturing processes and is able to offer high-quality parts at excellent prices.

Upload your design files for a fast quote, accurate lead times, and free DFM analysis.

*Please attach any format including STEP, STP, STL, IGS, IGES, PRT, SLDPRT, SAT, DWG, PDF, X_T, RAR.

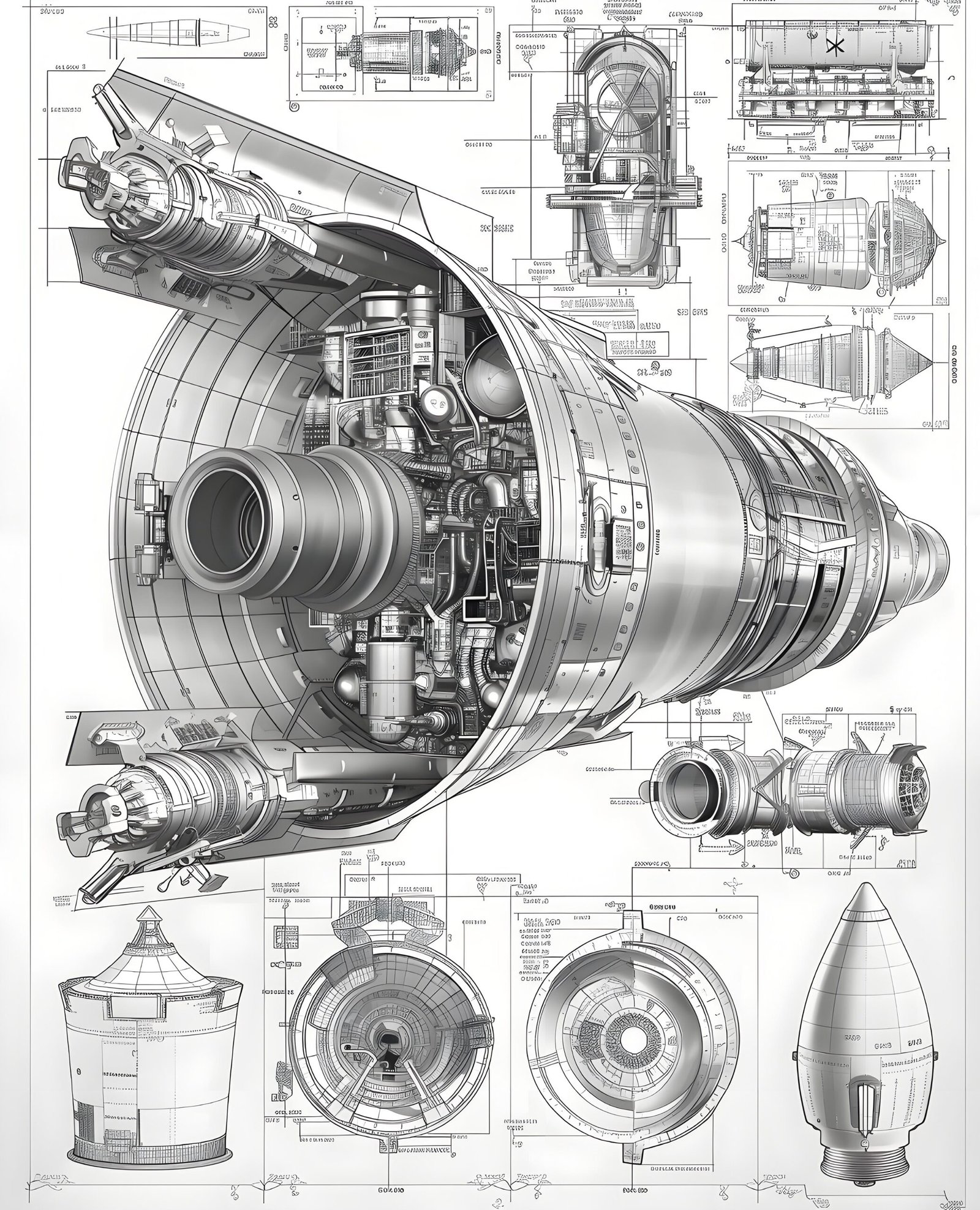

– Applications: Structural components, engine parts, turbine blades, and aircraft frames.

– Materials: Aluminum alloys (e.g., 6061, 7075) and titanium for their high strength-to-weight ratio and corrosion resistance.

– Machines: Haas UMC-500 Series and DMG’s 5-axis machines are designed for multi-sided and complex aerospace parts.

– Applications: Turbine components, valves, heat exchangers, and hydraulic parts.

– Materials: Copper (for thermal conductivity) and corrosion-resistant alloys like Inconel.

– Machines: EMCO’s large-frame gantry mills handle heavy-duty machining for industrial equipment.

– Applications: Weapon components, submarine parts, and radar systems.

– Materials: Marine-grade stainless steel and titanium for durability in harsh environments.

– Applications: Architectural models, custom fixtures, and decorative elements.

– Materials: Wood, PVC, and acrylic for prototyping; aluminum for structural parts.

– Machines: SIBO engineering’s multi-head CNC machines process wood and composites for brush handles and decorative items.

– Applications: Engine components, transmission parts, car accessories, and lightweight structural elements.

– Materials: Steel (e.g., stainless steel 304), aluminum, and carbon fiber composites.

– Machines: Mazak series and Haas VF Series vertical machining centers are optimized for automotive part production.

– Applications: Surgical instruments, prosthetics, dental implants, and orthopedic devices.

– Materials: Stainless steel (316L for corrosion resistance), titanium, and biocompatible plastics like PEEK.

-Machines: High-speed 5-axis machines (e.g., DMG Mazak) are used for intricate dental prostheses and microfluidic components.

– Applications: Injection molds, die-casting tools, and precision jigs.

– Materials: Hardened steel, Delrin (POM), and high-speed steel (HSS).

– Machines: DMG’s high-speed milling systems and TRIMILL’s rigid gantry mills ensure accuracy for mold production.

Jupai committed to providing suitable CNC machining services to meet or exceed customer expectations.

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

The first article under $200 is free.( Background investigation required.)

At present, the automatic quotation of CNC is for reference only, and the actual discount is subject to manualcalculation. After submitting the inguiry, a professional customer service will communicate with you within 12 hours.

Best CNC Machined Parts Manufacturer and Factory in China.

Offer Fast and Cost-Effective One-Stop CNC Machining Services.