Upload your design files for a fast quote, accurate lead times, and free DFM analysis.

*Please attach any format including STEP, STP, STL, IGS, IGES, PRT, SLDPRT, SAT, DWG, PDF, X_T, RAR.

5 Axis CNC Machining has opened the possibility for parts to be ‘Done in One’, reducing setup and reorientation costs. With intelligent programming, data paths are trialled and tool paths are perfected in advance of production, achieving efficiency and accuracy.

From simple components to highly complex specifications, Jupai select the best machining equipment to produce your 5 Axis Machined parts based on suitability and price, never compromising on quality.

– Applications: Turbine blades, engine mounts, structural components (e.g., wing ribs, fuselage parts), and landing gear systems.

– Key Features: High precision for complex geometries, ability to machine lightweight alloys (e.g., titanium, aluminum) and composites.

– Machines: DMG Series, Mazak, and Haas UMC Series (multi-sided machining).

– Advantages: Reduced setups, improved surface finish, and compatibility with high-strength materials.

– Applications: Wind turbine shafts, nuclear reactor fittings, hydraulic pump components, and solar panel brackets.

– Materials: Inconel, duplex stainless steel, and carbon composites for extreme environments.

– Machines: EMCO’s ECOMILL series (large-scale machining for industrial parts), Parpas’ SPEEDLINER (high-speed gantry systems).

– Applications: Missile components, submarine valve systems, and radar housings.

– Materials: Marine-grade aluminum (5052/5083), super duplex stainless steel.

– Machines: Haas EC-1600ZT-5AX (large-part machining with integrated rotary platter).

4. Medical & Dental

– Applications: Orthopedic implants, surgical instruments, dental prostheses, and MRI machine components.

– Materials: Biocompatible titanium, stainless steel (316L), and PEEK plastic.

– Precision: Achieves micron-level accuracy (e.g., ±0.005mm) for critical medical devices.

– Machines: DMG-DMU80MONO(compact, high-precision design).

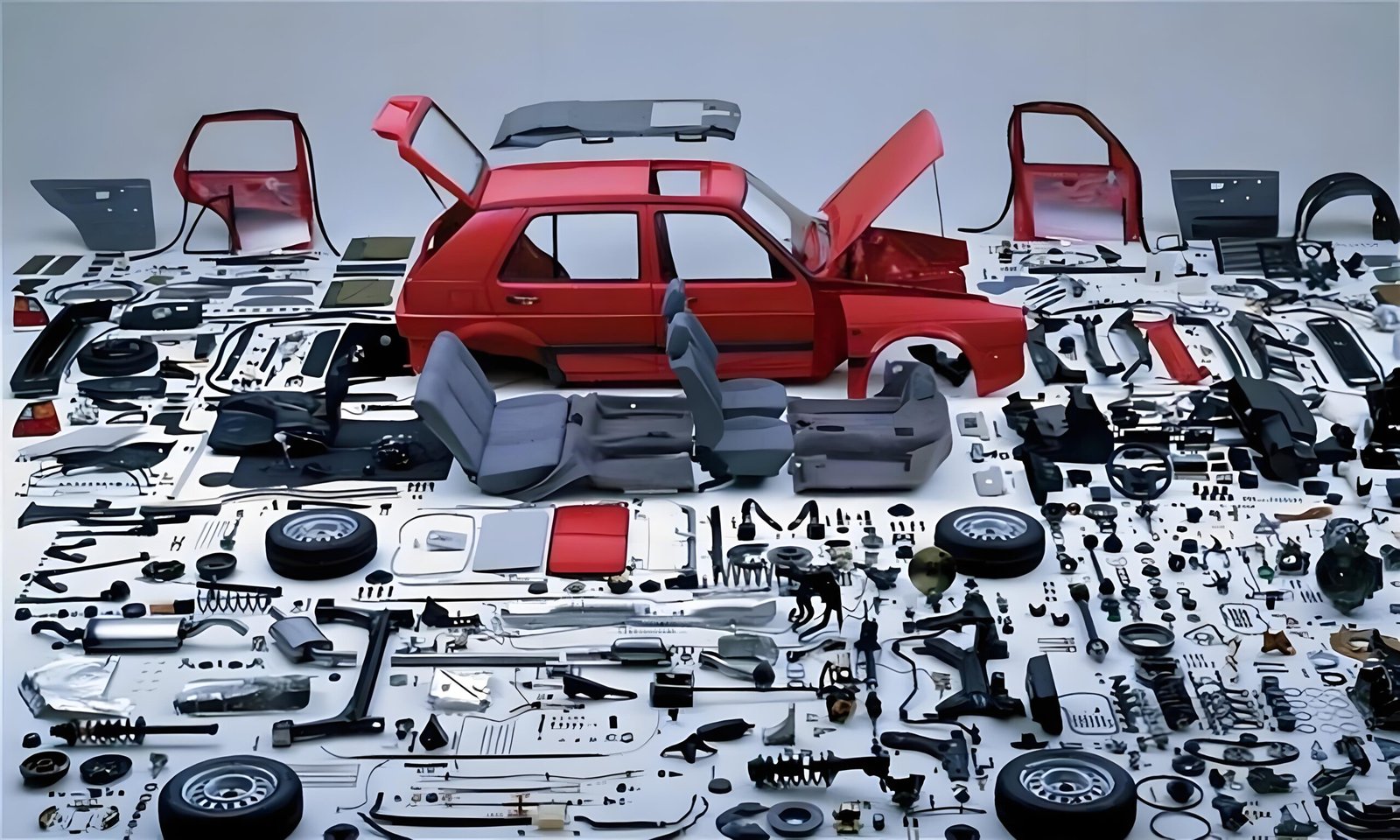

– Applications: Engine blocks, transmission housings, lightweight structural components, and high-performance racing parts (e.g., cylinder heads).

– Key Features: Efficient machining of complex curves and undercuts, rapid prototyping for custom designs.

– Examples: Ultra Pro Machining specializes in race engine components like cylinder heads for NASCAR and NHRA.

– Machines: Promac’s ETESIAN THMC 2.0 (horizontal spindle for automotive molds).

– Applications: Injection molds, die-casting tools, and precision jigs.

– Key Features: 5-axis machines reduce manual intervention, enabling intricate geometries and smooth finishes.

– Examples: Belotti MDL Series (mold finishing for aerospace composites), DDPROTOTYPE’s rapid prototyping for complex molds.

– Advantages: High-speed finishing and reduced EDM dependency.

– Applications: Heat sinks, connector pins, smartphone casing components, and drone motor shafts.

– Materials: Aluminum (for conductivity), brass, and Delrin (POM).

– Machines: Compact 5-axis routers like Jinan Blue Elephant’s dual-table systems (efficient small-part production).

Complex Geometry Handling: Simultaneous 5-axis movement allows machining of undercuts, deep cavities, and multi-faceted parts in a single setup.

Reduced Production Time: Eliminates multiple clamping steps, minimizing manual errors and accelerating workflows.

Superior Surface Quality: Short cutting tools reduce vibration, enabling smoother finishes.

Material Versatility: Compatible with metals, composites, ceramics, and plastics.

Up to now, in order to meet the increasingly precise tolerances and complex structural requirements of our customers, Jupai purchase a variety of precision 5-axis machining equipment, such as DMG, Mazak, Hass, Fanuc, etc. We are proud to produce all kinds of difficult parts for our customers, and this is where our value lies.

In addition to the above precision machining capabilities, Jupai also can meets your post-processing requirements of mechanical grinding, chemical treatment, surface heat treatment, spraying surface through our network of surface treatment suppliers in China, no matter rapid prototyping or mass production.

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

The first article under $200 is free.( Background investigation required.)

At present, the automatic quotation of CNC is for reference only, and the actual discount is subject to manualcalculation. After submitting the inguiry, a professional customer service will communicate with you within 12 hours.

Best CNC Machined Parts Manufacturer and Factory in China.

Offer Fast and Cost-Effective One-Stop CNC Machining Services.