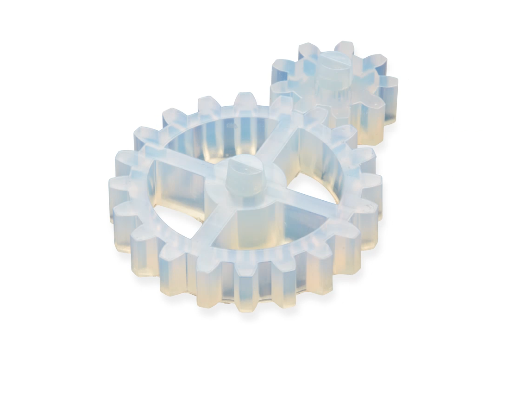

3D printing technology (also known as Additive Manufacturing, AM) is an advanced manufacturing technology that directly constructs three-dimensional objects based on digital design models by stacking materials layer by layer. Its core principle is to transform computer-generated 3D models into actual physical objects, usually using materials such as plastics, metals, ceramics, etc., which are realized through different processes such as Fused Deposition Modeling (FDM), Stereo Light Curing (SLA), and Selective Laser Sintering (SLS). Unlike traditional subtractive manufacturing (e.g., cutting, milling), 3D printing is an “additive” process, capable of producing products with complex geometries and structures.

Upload your design files for a fast quote, accurate lead times, and free DFM analysis.

Please attach your 2D CAD drawings and 3D CAD models in any format including STEP, IGES, DWG, PDF, STL, etc. If you have multiple files, compress them into a ZIP or RAR. Alternatively, send your RFQ by email to

Metal 3D printing (selective laser melting SLM, electron beam melting EBM). Widely used in the manufacture of high-strength, high-temperature-resistant and complex parts, such as engine parts, turbine blades, etc;

Plastic 3D printing (stereolithography SLA, fused deposition molding FDM). For the production of low-cost, non-bearing parts.

.png)

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

The first article under $200 is free.( Background investigation required.)

At present, the automatic quotation of CNC is for reference only, and the actual discount is subject to manualcalculation. After submitting the inguiry, a professional customer service will communicate with you within 12 hours.

Best CNC Machined Parts Manufacturer and Factory in China.

Offer Fast and Cost-Effective One-Stop CNC Machining Services.