- Polishing:Achieving a high-gloss, smooth finish on metal and plastic surfaces, enhancing both visual appeal and corrosion resistance.

- Anodizing:A versatile surface treatment for aluminum parts, offering enhanced durability, corrosion resistance, and aesthetic finishes, available in a variety of colors.

- Passivation:Specialized treatment for stainless steel, removing impurities and improving resistance to corrosion, oxidation, and wear.

- Electroplating: Applying thin metallic coatings to improve wear resistance, hardness, and corrosion protection.

- Powder Coating: A durable, long-lasting coating solution for various metals, providing both functional and aesthetic benefits, including resistance to chipping, fading, and scratching.

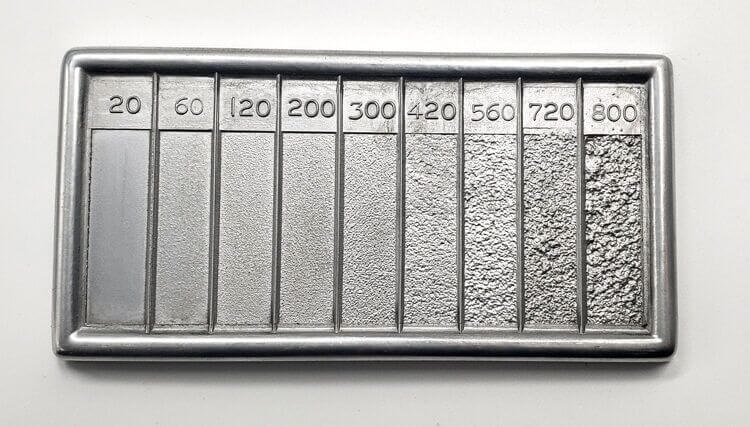

- Sandblasting and Shot Peening: Effective methods for cleaning, smoothing, and strengthening surfaces, which improve fatigue resistance and part longevity.

- Laser Etching and Marking:Precision surface marking for traceability, branding, and part identification, using advanced laser technology for high-definition results.