这是示例文本,单击 “编辑” 按钮更改此文本。

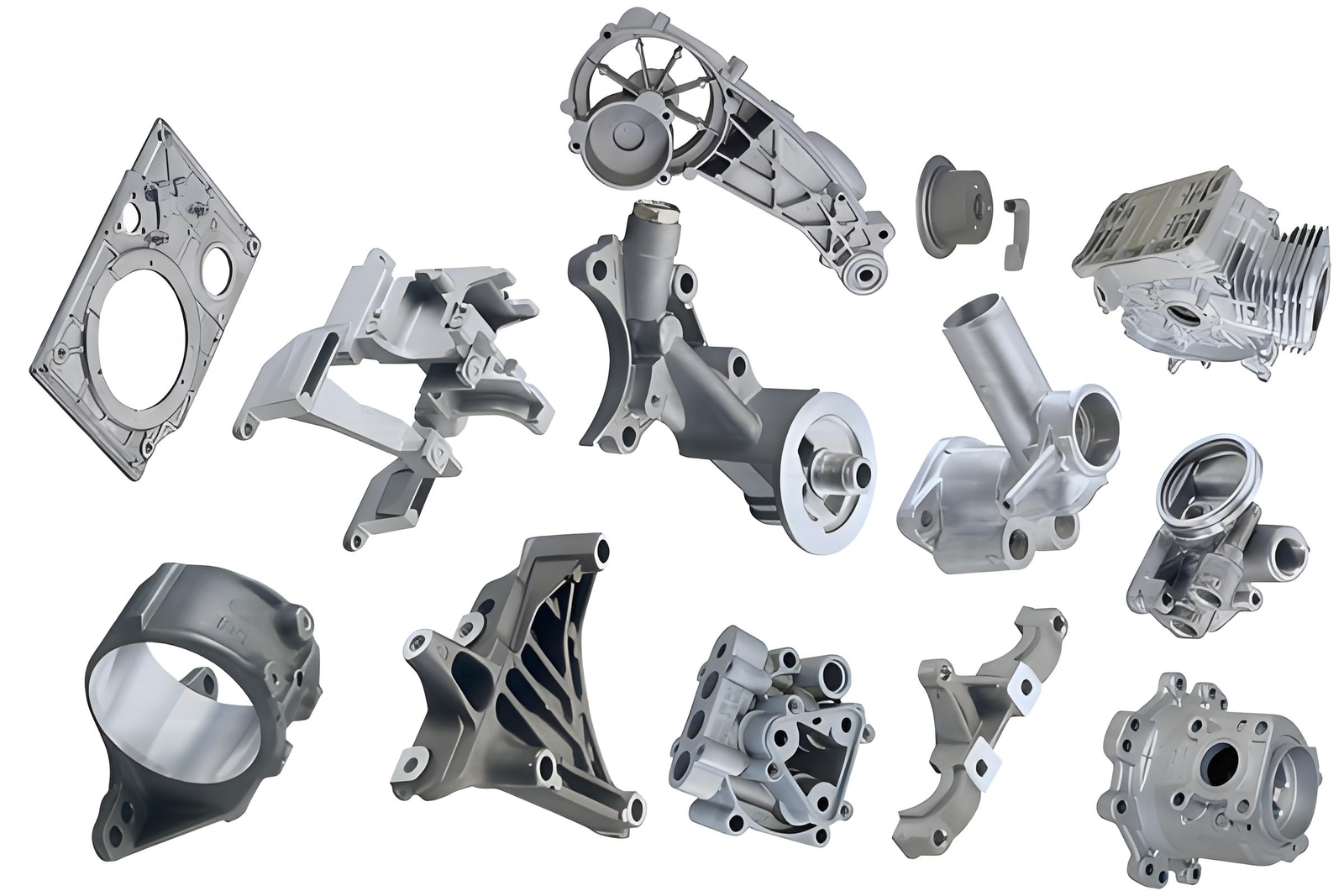

As a professional partner in the field of precision parts processing in the automotive industry, Jupaicnc provides customers with high-precision and high-reliability component solutions with advanced CNC machining technology, intelligent production systems and rich industry experience. The company uses advanced machine tools such as five-axis linkage machining centers and turning and milling equipment, combined with a strict IATF 16949 quality management system to ensure that the dimensional accuracy of various metal parts reaches the micron level, fully meeting the stringent requirements of key parts such as engines and transmission systems; at the same time, through automated production lines and flexible manufacturing systems, efficient mass production and rapid delivery are achieved to help customers optimize supply chain efficiency. Jupaicnc has been deeply involved in automotive parts processing for many years. Driven by technology and based on quality, it helps automakers improve their competitiveness and is a trustworthy precision processing partner.

JUPAICNC provides the automotive industry with full-dimensional precision machining technology empowerment, covering everything from core components to intelligent production systems. With five-axis linkage machining centers and high-precision turning and milling equipment, we can perfectly process key components such as engine blocks and gearbox gears, with a tolerance accuracy of up to ±0.005mm. Through the intelligent MES production management system, digital control of the entire process from raw materials to finished products is achieved to ensure quality traceability and production stability. In response to the lightweight needs of new energy vehicles, we have unique process advantages in the processing of aluminum alloys and carbon fiber composite materials, which can help customers achieve a weight reduction of more than 30%. At the same time, the flexible production line design supports rapid changeover to meet the customized needs of multiple varieties and small batches.

Tensile strength 500-1500MPa, used for body structural parts, improving collision safety while achieving lightweight.

Low density (2.7g/cm³), corrosion resistance, used in engine blocks and body panels, with significant weight reduction effects.

High strength, good toughness, used for crankshafts and differential housings, balancing cost and performance.

30% glass fiber reinforced, high temperature resistant, low friction, used for intake manifolds and bearing covers, replacing metal to reduce weight.

Its specific strength is 5 times that of steel and is used in battery boxes and structural parts of new energy vehicles, making it extremely lightweight.

High strength, corrosion resistance, used in high-performance car connecting rods and exhaust systems, but the cost is relatively high.

A dense oxide layer is formed on the surface of aluminum alloy through electrolysis, which improves corrosion resistance (salt spray test for more than 500h) and enhances surface hardness (HV800+). It is suitable for new energy battery housings, motor end covers and other parts.

Using low-temperature technology to generate a 50-100μm thick oxide film with a surface hardness of HV1200, it is used in scenarios that require wear resistance, such as transmission valve bodies and hydraulic components.

The electroplating layer has a thickness of more than 12μm, and the neutral salt spray test is more than 720h without rusting, meeting the long-term anti-corrosion requirements of automotive bolts, clamps and other parts.

Vacuum ion plating of titanium/chrome achieves mirror-grade gloss (Ra≤0.1μm) and scratch resistance. It is used for exterior parts such as door handles and signs, taking into account both beauty and durability.

Epoxy resin powder is sprayed and cured to form a 80-120μm coating that is stone-impact and chemical-resistant, suitable for outdoor exposed parts such as chassis parts and suspension components.

Electric Drive Motor Shaft: 42CrMo4 high-frequency quenching, surface roughness Ra0.4μm, torque capacity ≥2000N·m.

Hydrogen Fuel Cell Bipolar Plate: 5 316L stainless steel etching, flow channel accuracy ±0.02mm, conductivity >1000S/cm.

Smart Suspension Valve Body: 17-4PH stainless steel precision EDM, oil channel tolerance ±5μm, response time <10ms.

Sensor Housing: PPS injection molding + metal insert embedding, IP67 protection, vibration resistance 5G (IATF 16949 certified).

Thermal Management Valve Block: 6063 aluminum diffusion welding, burst pressure ≥50Bar, leakage rate <0.1mL/min.

Turbocharger Impeller: Inconel alloy 5-axis milling, temperature resistance up to 900°C with dynamic balance accuracy ≤0.5g·mm.

Transmission Planetary Gear: 20MnCr5 carburized steel precision gear honing, tooth surface hardness HRC60-62, noise <68dB.

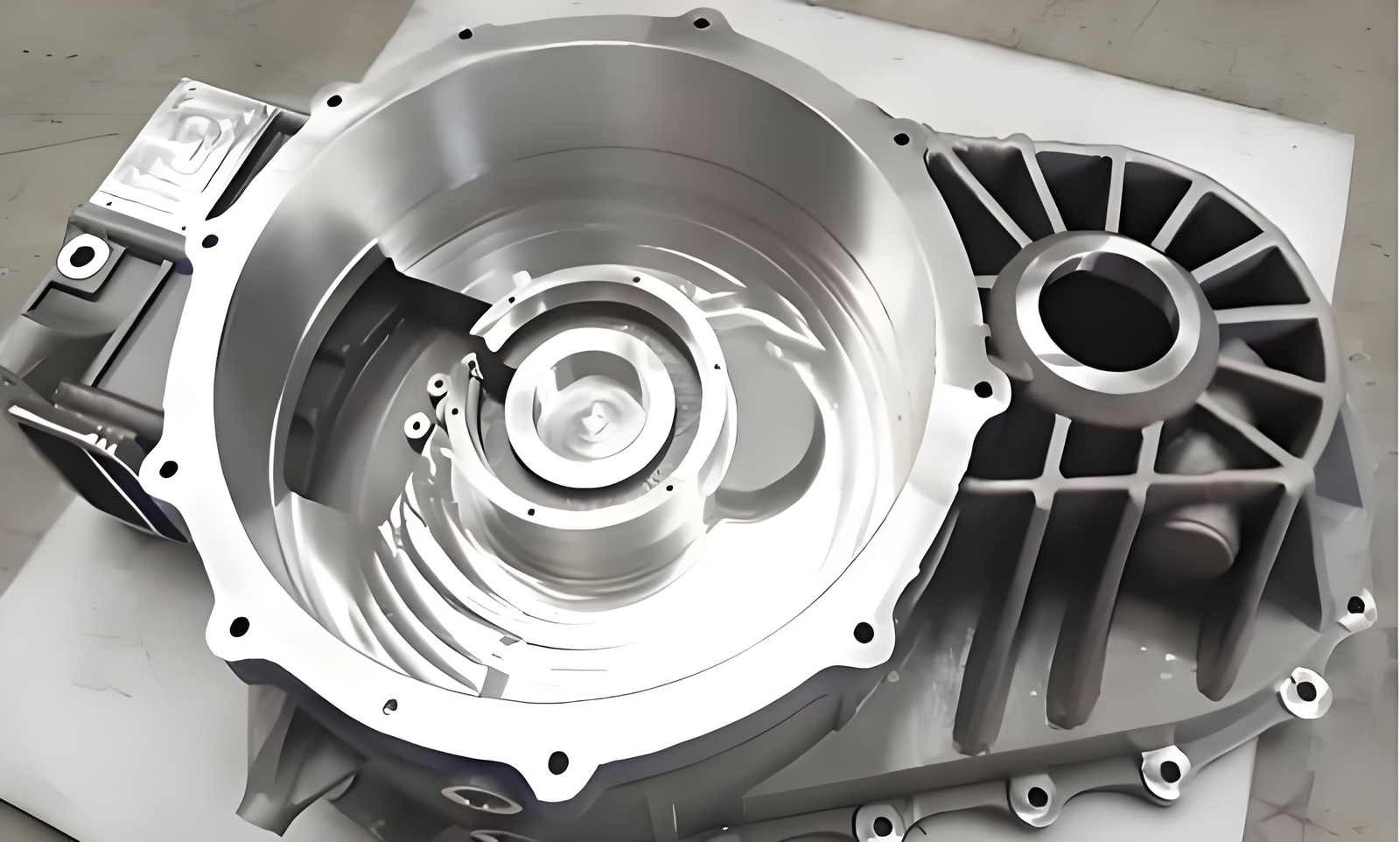

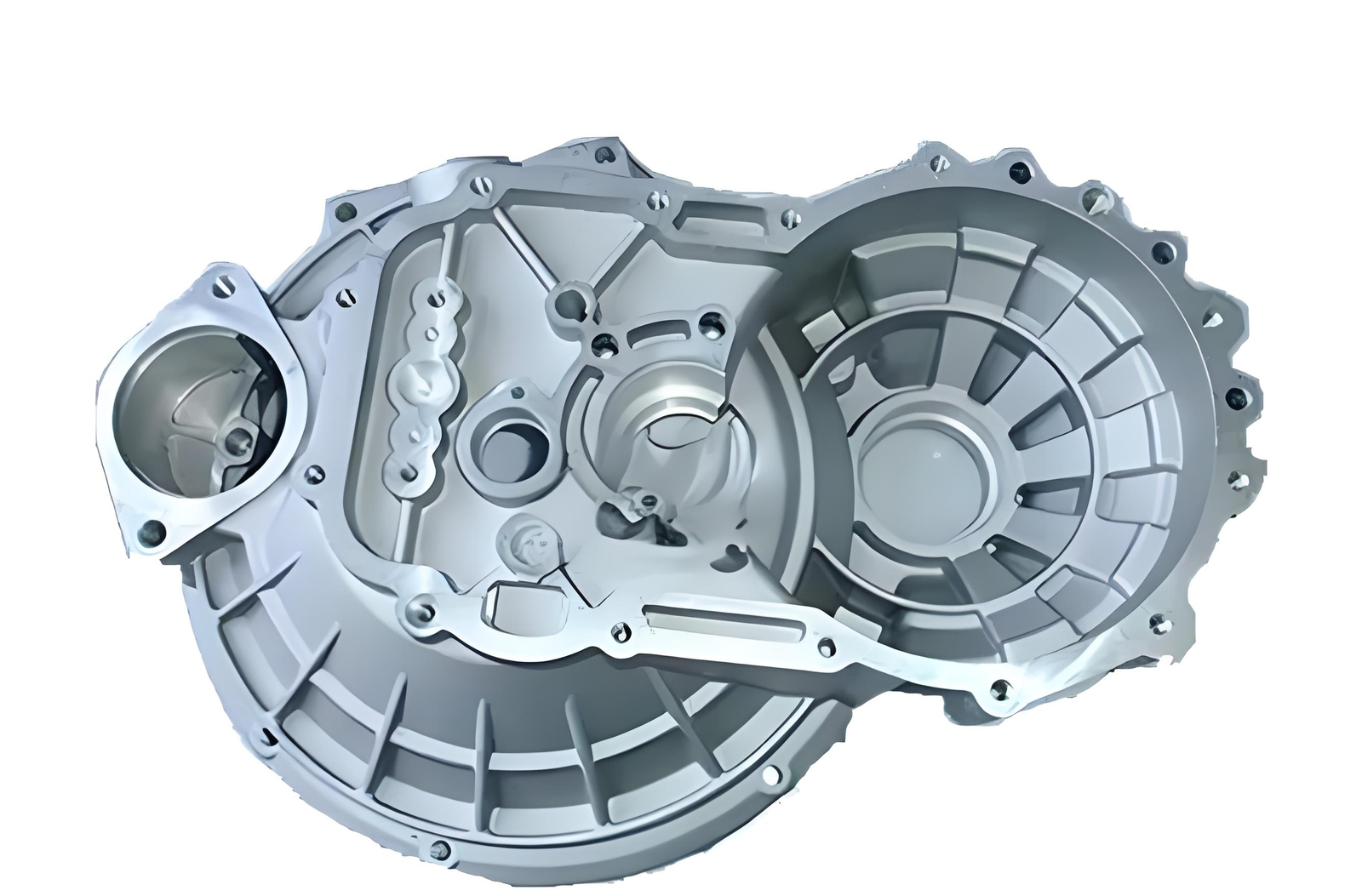

Cylinder Block/Head: Aluminum alloy high-pressure casting + 5-axis machining, combustion chamber sealing surface flatness ≤0.02mm.

Drive Shaft: 42CrMo4 high-frequency quenching, surface hardness HRC55-58, torque capacity ≥3000N·m.

Connecting Rod: Titanium alloy CNC machining, 30% weight reduction with tensile strength ≥1000MPa.

High-Pressure Fuel Rail: Stainless steel deep-hole drilling, inner wall roughness Ra≤0.8μm, pressure resistance >200Bar.

Motor Shaft: S45C steel hard turning, coaxiality ≤0.01mm, compatible with 800V electric drive systems.

Suspension Control Arm: 7075 aluminum alloy 5-axis machining, 40% lightweight design with fatigue life >500,000 cycles.

Oil Pump Housing: ADC12 die-casting + CNC finishing, leakage rate <0.1mL/min.

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

The first article under $200 is free.( Background investigation required.)

At present, the automatic quotation of CNC is for reference only, and the actual discount is subject to manualcalculation. After submitting the inguiry, a professional customer service will communicate with you within 12 hours.

Best CNC Machined Parts Manufacturer and Factory in China.

Offer Fast and Cost-Effective One-Stop CNC Machining Services.