这是示例文本,单击 “编辑” 按钮更改此文本。

Micron machining

5-axis CNC technology (accuracy ±0.003mm) supports complex surface processing of titanium alloy and nickel-based superalloy; The intelligent cutting parameter optimization system controls the tool load in real time and reduces the machining loss by 22%.

Complex Geometry Fabrication

Achieves intricate shapes (e.g., turbine disks, airfoils) via CNC programming, meeting aerodynamic and lightweight requirements

Automated Production

Minimizes human errors and enhances efficiency through CNC automation, ensuring consistency in large-scale manufacturing

High specific strength, corrosion resistance, easy processing, used for fuselage frame, fuel storage tank and other structural parts

High specific strength (1.3 times of aluminum alloy), high temperature resistance (450~500℃), corrosion resistance, suitable for engine compressor blades, high temperature cabin

Lightweight (density < 1/4 of steel), tensile strength of more than 3500MPa, used for wings, missile shells and other lightweight high-strength parts

High temperature (> 1000℃), creep resistance, used in engine turbine blades and other extreme high temperature environment

High tensile strength, fatigue resistance, used for bearing, transmission gear and other high-load structural parts

High strength (2~3 times of carbon fiber), high temperature resistance (1500℃), suitable for high temperature protection materials and lightweight structural parts

high-energy laser melting metal powder, forming 850℃ high temperature coating on the surface of fuel nozzle, thermal shock resistance improved by 3 times

1500HV ceramic oxide film is generated on the surface of aluminum alloy by high voltage discharge, and the salt spray corrosion resistance is improved by 60%

Vacuum deposition CrN or TiAlN coating, titanium alloy fastener surface hardness ≥2200HV, friction coefficient reduced by 40%

Dense alumina film generated by electrolysis, corrosion resistance up to 1000 hours of neutral salt spray test, suitable for satellite structural parts

No electrolytic deposition of nickel-phosphorus alloy layer, uniform coverage of complex cavity, hardness 600HV, acid and alkali corrosion resistant

Titanium alloy integral blade disc : the core part of engine compressor, five-axis linkage processing, surface accuracy of ±0.005mm.

Aluminum alloy honeycomb structure : 50% weight reduction by high-speed milling, used for wing sandwich structure.

Heat-resistant steel fuel nozzle : deep hole drilling micro-hole (diameter 0.3mm), fuel atomization efficiency increased by 30%.

Titanium alloy rocket nozzle : multi-axis turning thread sealing structure, resistant to high pressure and high temperature oxidation environment.

Stainless steel hydraulic spool : nano level turning, with clearance ≤3μm, to ensure zero leakage of hydraulic system.

Stainless steel hydraulic spool : nano level turning, with clearance ≤3μm, to ensure zero leakage of hydraulic system.

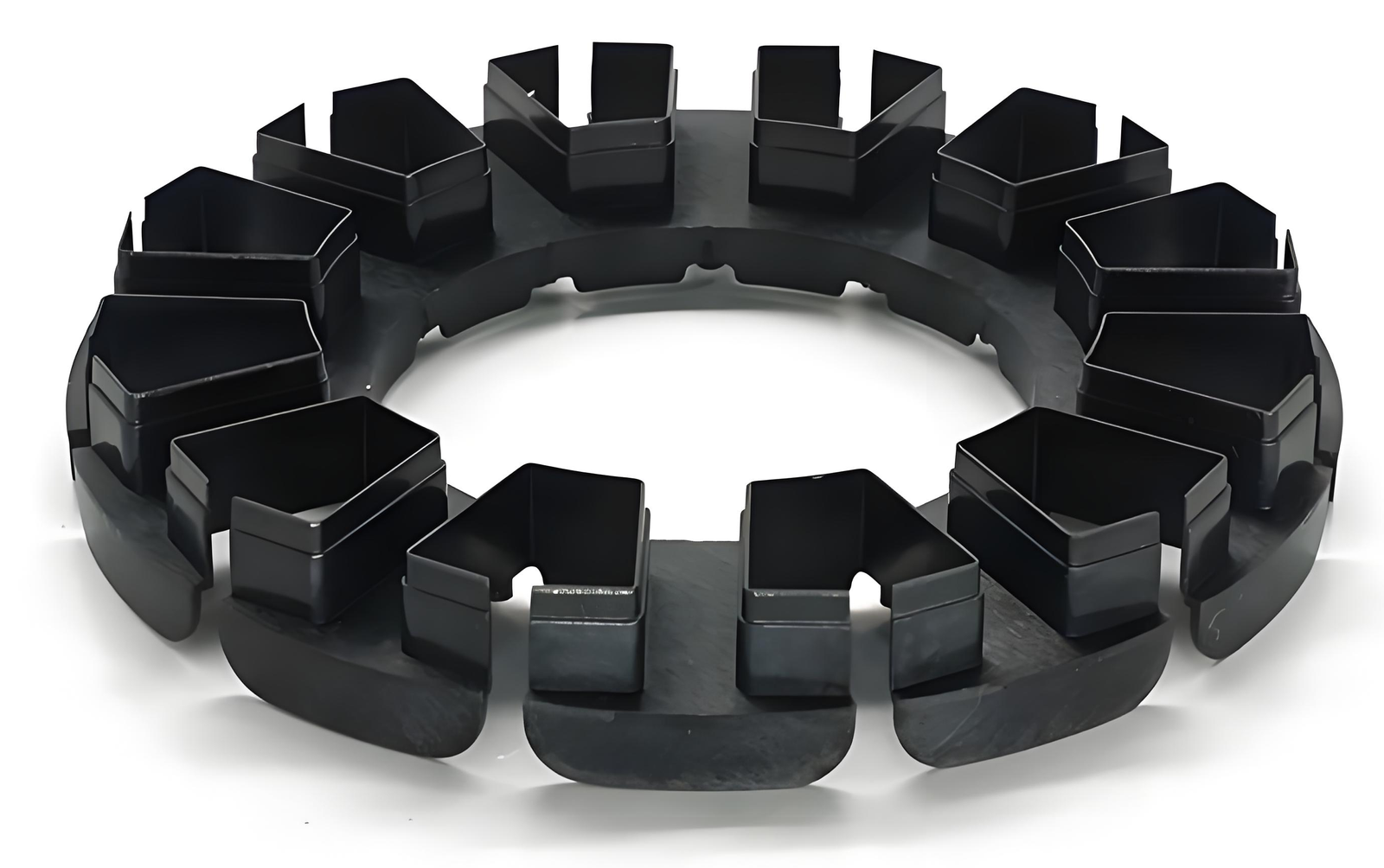

Superalloy turbine disk : EDM wire-cut mortise groove (accuracy ±0.01mm), improve engine assembly reliability.

Titanium alloy fasteners : laser marking tracing, shear strength ≥1000MPa, spacecraft structure connection key parts.

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

The first article under $200 is free.( Background investigation required.)

At present, the automatic quotation of CNC is for reference only, and the actual discount is subject to manualcalculation. After submitting the inguiry, a professional customer service will communicate with you within 12 hours.

Best CNC Machined Parts Manufacturer and Factory in China.

Offer Fast and Cost-Effective One-Stop CNC Machining Services.