这是示例文本,单击 “编辑” 按钮更改此文本。

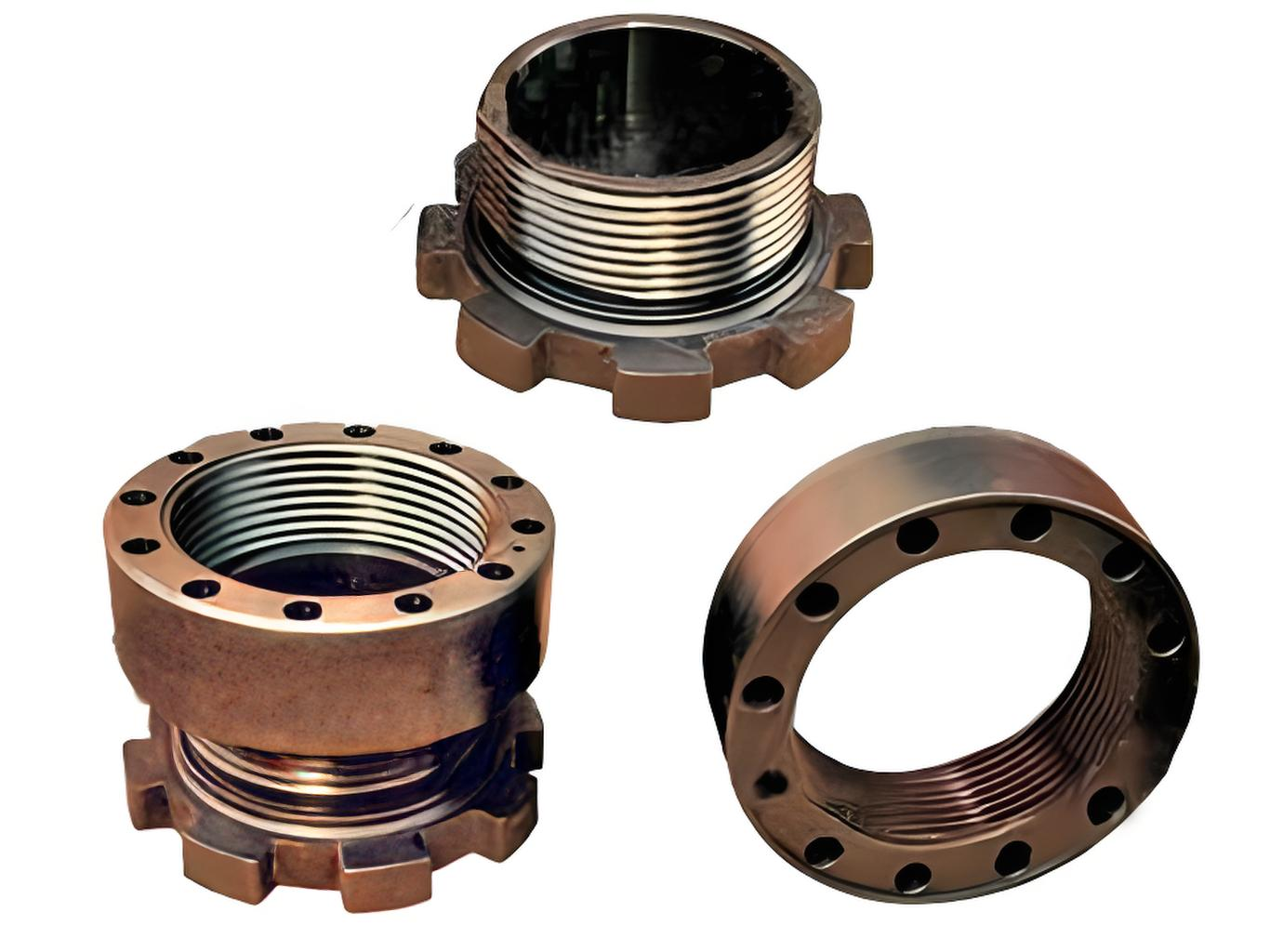

JupaiCNC passed ISO9001, Marine oil field machining components rely on five-axis linkage ultra-precision machining technology, combined with Inconel/Ti-6Al-4V and other special alloy materials, the precision of key components up to ±0.005mm, nano-coating and deep nitriding treatment, corrosion resistance increased by 60%, Can withstand 1000℃ high temperature and 180MPa high pressure environment. Jupai extends component life up to 120,000 hours through four-stage gas seal testing and stress/temperature/wear/vibration suppression technology.

Reliability in extreme working conditions

Using Inconel718 and other corrosion resistant alloys and five-axis linkage processing technology, the precision of key components is up to ±0.005mm, and the giant has passed ISO 9001

Environmental adaptation

Oilfield equipment must withstand extreme temperatures/pressures, corrosive substances, abrasive dust, humidity, explosive hazards, and ensure compliance with environmental regulations.Increase full cycle efficiency

Reduce processing costs

Cutting parameters are optimized through edge computing, material utilization is increased by 25%, and delivery time is reduced by 40% compared with traditional processes.

Lightweight (density 4.5g/cm³), tensile strength ≥900MPa, Cl⁻ ion corrosion resistance, suitable for drilling pipe, pump valve and other high-pressure components, fatigue life is 3 times higher than steel

High temperature (200℃) and high pressure (80MPa), sulfide stress cracking resistance, five-axis processing accuracy of ±0.005mm, for deep well valve sets and LNG ship cryogenic pump body.

PREN value ≥43 (Cr+3.3Mo+16N), resistance to pitting corrosion and seawater uniform corrosion, yield strength ≥550MPa, suitable for high-pressure pipelines and tree sealing parts

Yield strength 690MPa, Marine salt spray corrosion resistance, elongation ≥14%, suitable for drilling platform structural parts, submarine pipelines, impact toughness KV2≥31J

Sea water corrosion resistance and −20~200℃ temperature difference, tensile strength ≥15MPa, used for underwater tree seal ring, can withstand 1500 meters deep sea pressure

Surface galvanized treatment, salt spray life of more than 3000 hours, tensile strength ≥1000MPa, suitable for API standard anchor chain and deep sea mooring system fasteners

Hardness HV2200, salt spray life of more than 5000 hours, for valve stem, pump shaft, friction coefficient reduced by 40%.

Electroplating (Zn, Ni) and electroless plating (Ni-P) to resist harsh environments

316L stainless steel surface roughness Ra≤0.2μm, eliminate CNC tool marks, flow resistance reduced by 18%.

Surface cleaning, stress relief, and roughness control via abrasive/impact methods

50μm ceramic film is formed on the surface of aluminum alloy, breakdown voltage > 3000V, Cl⁻ corrosion resistance, suitable for sensor shell.

Tree sealing flange : 316L stainless steel, laser cladding WC-Co coating to improve the compressive strength of the sealing surface

Deep sea manifold connector : titanium alloy Ti-6Al-4V, salt spray life of more than 5000 hours

Hydraulic control block : 40CrNiMoA alloy steel, nano AlCrN coating reduces friction coefficient by 40%

Guide base bushing : surface micro arc oxidation treatment to form 50μm ceramic layer

Anchor chain connection pin : 42CrMo4 high strength steel, deep nitriding treatment to make the surface hardness ≥HRC60

LNG cryogenic pump shaft : Monel K500 nickel-copper alloy, low temperature ion sulfide technology to achieve friction coefficient ≤0.03

Submarine sensor shell : 6061-T6 aluminum alloy, electrochemical polishing roughness Ra≤0.2μm

Pressure balance piston : 17-4PH precipitation hardened steel, composite nickel plating to improve seawater erosion resistance

Underwater robot joint : TC4 titanium alloy, five-axis machining multi-degree of freedom surface, repeated positioning accuracy 0.005mm

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

The first article under $200 is free.( Background investigation required.)

At present, the automatic quotation of CNC is for reference only, and the actual discount is subject to manualcalculation. After submitting the inguiry, a professional customer service will communicate with you within 12 hours.

Best CNC Machined Parts Manufacturer and Factory in China.

Offer Fast and Cost-Effective One-Stop CNC Machining Services.