这是示例文本,单击 “编辑” 按钮更改此文本。

1. High-precision of complex component manufacturing The five-axis linkage machining center breaks through the micron-level machining bottleneck of complex curved surface components such as the pressure-resistant cavity of deep-sea drilling equipment and the sealing ring of nuclear power reactors, ensuring the reliability and life of equipment in extreme environments, and helping to increase oil and gas exploration efficiency by 20%. 2. Intelligent process optimization Based on the adaptive control system of AI algorithm, compensates for machining errors in real time, realizes lightweight blade molds (weight reduction of 15%) and simultaneous optimization of surface accuracy in the wind power field, and shortens the R&D cycle of wind turbines by 40%; combined with thermal error compensation technology, the processing yield of nuclear power precision components is increased to 99.6%. 3. Digital full-chain collaboration Relying on the industrial Internet platform, a closed-loop system from digital twin simulation to intelligent production line integration is built to achieve dynamic tuning of process parameters in energy storage equipment manufacturing, shortening the delivery cycle by 30% and reducing the overall cost by 18%.

Excellent corrosion resistance and high temperature resistance, suitable for corrosive environment components such as oil and gas pipelines, nuclear power valves, etc.

It has remarkable lightweight properties (density is only 1/3 of steel), high strength and corrosion resistance, and is mostly used in wind turbine blade frames and lightweight energy storage housings.

Excellent thermal conductivity (thermal conductivity up to 380 W/m·K), used in thermal management scenarios such as generator radiators and transformer conductive connectors

High wear resistance and outstanding vibration absorption performance, suitable for heavy-duty gas turbine bases, hydraulic turbine housings and other load-bearing structural parts

Nylon (PA66) has strong fatigue resistance, and PPS has a temperature resistance of up to 240°C. It is used in lightweight scenarios such as insulation parts of electric drive systems and chemical-resistant seals.

Carbon fiber reinforced resin-based materials have a specific strength five times higher than steel and are used in extreme working conditions such as pressure-resistant shells of deep-sea drilling equipment and floating wind turbine blades

For aluminum alloy components, a 10-100μm ceramic oxide film is generated on the surface through high-voltage electrolysis. The hardness reaches HV1500 and the temperature resistance exceeds 2000℃. It is used for corrosion protection of wind turbine pitch bearings and energy storage boxes, and the salt spray test life is increased by more than 3 times.

A 50-80μm amorphous coating is deposited on the surface of cast iron valves and pipes, and the H₂S corrosion resistance reaches the highest standard of ISO 15156. It is suitable for shale gas wellhead devices and the service life is extended to 8 years.

The aluminum alloy energy storage battery bracket is hard anodized (film thickness 25μm), and nano-sealing agent is superimposed to fill the micropores. The voltage breakdown strength reaches 35kV/mm, and the insulation performance meets the IEC 61439 standard.

A multi-layer electroplating process is used to deposit a nickel-chromium composite coating (thickness 50-100μm) on the surface of the stainless steel substrate. The coating hardness reaches HV600-800, and the wear resistance is 60% higher than that of traditional spraying. Applied to gas turbine blades, shale gas valves and other scenarios, the H₂S corrosion resistance meets the ISO 15156 standard.

The sealing surface of the nuclear power flange is repaired through 3D printing technology, using Inconel 625 alloy powder. The bonding strength between the cladding layer and the substrate is greater than 400MPa, the high-temperature creep resistance is improved by 60%, and the cost of spare parts replacement is reduced.

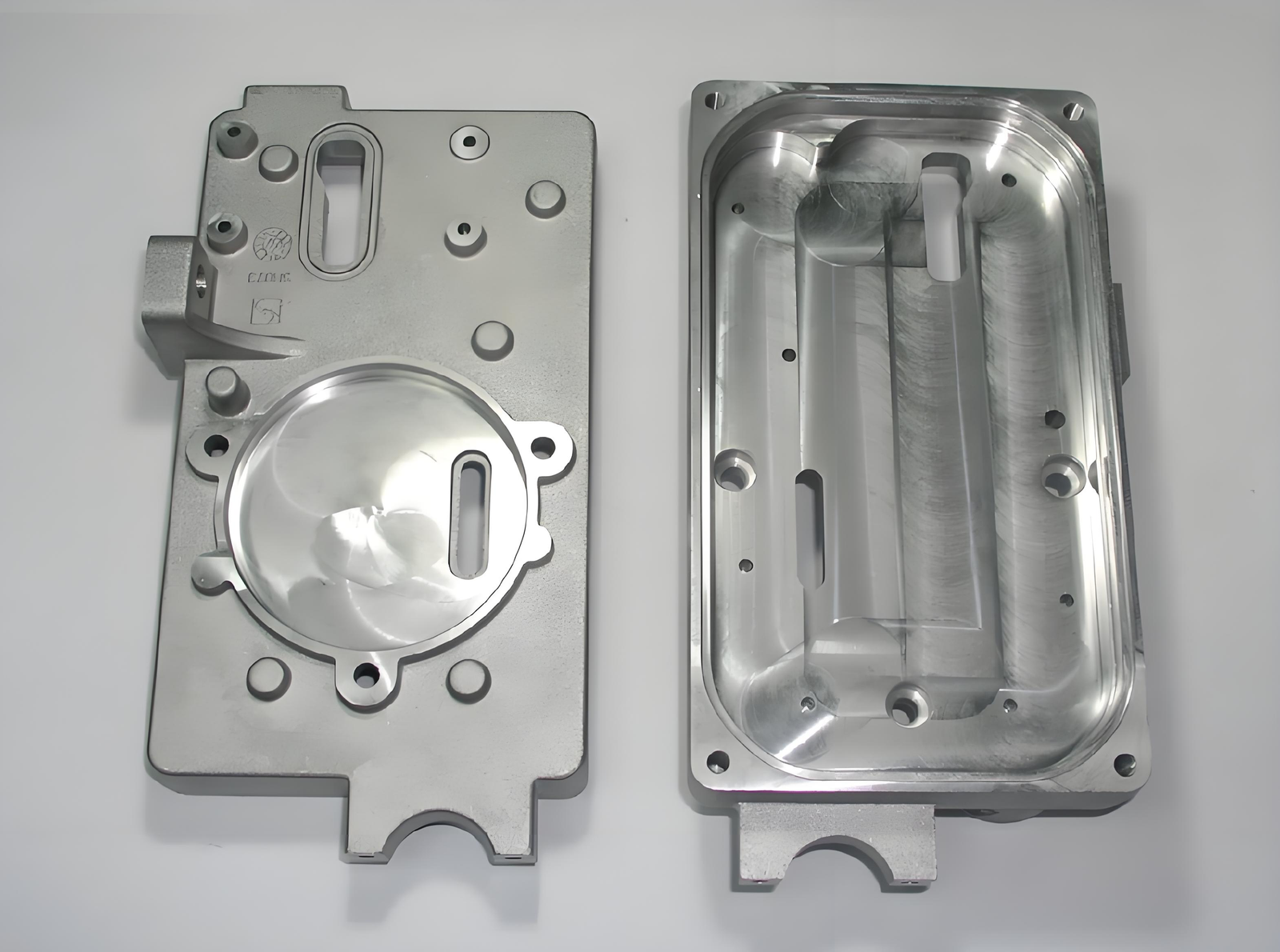

Wind turbine hub castings: Ductile iron five-axis machining, bearing strength up to EN-GJS-400 standard, suitable for wind turbines above 5MW.

Nuclear power main pump impeller: Stainless steel 3D printing + laser cladding, high temperature radiation resistance meets ASME III standard.

Solar tracking bracket: 6061-T6 aluminum alloy extrusion molding, dynamic load support > 5kN/m².

Shale gas wellhead valve body: Duplex steel forging CNC machining, hydrogen sulfide corrosion resistance up to NACE MR0175.

Energy storage battery module end plate: 7075 aluminum alloy micro-arc oxidation, insulation breakdown voltage > 30kV

Gas turbine turbine disc: Inconel 718 five-axis milling, high temperature fatigue life exceeds 100,000 times (ISO 12107)

Floating wind power anchor chain buckle: 42CrMo4 alloy steel supersonic spraying, salt spray resistance > 5000 hours

Hydrogen compressor piston rod: titanium alloy precision honing, surface roughness Ra ≤ 0.2μm

Nuclear waste container sealing cover: silicon carbide ceramic composite processing, radiation aging rate < 0.1% / year

Photovoltaic silicon wafer cutting guide wheel: hard alloy electroplated diamond, cutting line diameter accuracy ± 2μm

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

The first article under $200 is free.( Background investigation required.)

At present, the automatic quotation of CNC is for reference only, and the actual discount is subject to manualcalculation. After submitting the inguiry, a professional customer service will communicate with you within 12 hours.

Best CNC Machined Parts Manufacturer and Factory in China.

Offer Fast and Cost-Effective One-Stop CNC Machining Services.