这是示例文本,单击 “编辑” 按钮更改此文本。

Jupaicnc has become an ideal partner for robot component manufacturing with its high-precision processing technology and industry experience. We use imported five-axis CNC equipment (accuracy ±0.01mm) and strict quality inspection processes to ensure the durability and dynamic performance of key components such as robot arm joints and reducers. The mature one-stop service covers design optimization, material selection to mass production, supports the processing of special materials such as titanium alloy and carbon fiber, and meets the lightweight requirements of collaborative robots and high load requirements of industrial robots. Through flexible production lines and rapid response teams, we help customers shorten delivery cycles by 50% and reduce overall costs. Also, with more than 30 robotics industry project experiences, Jupaicnc provides reliable manufacturing support for your innovation.

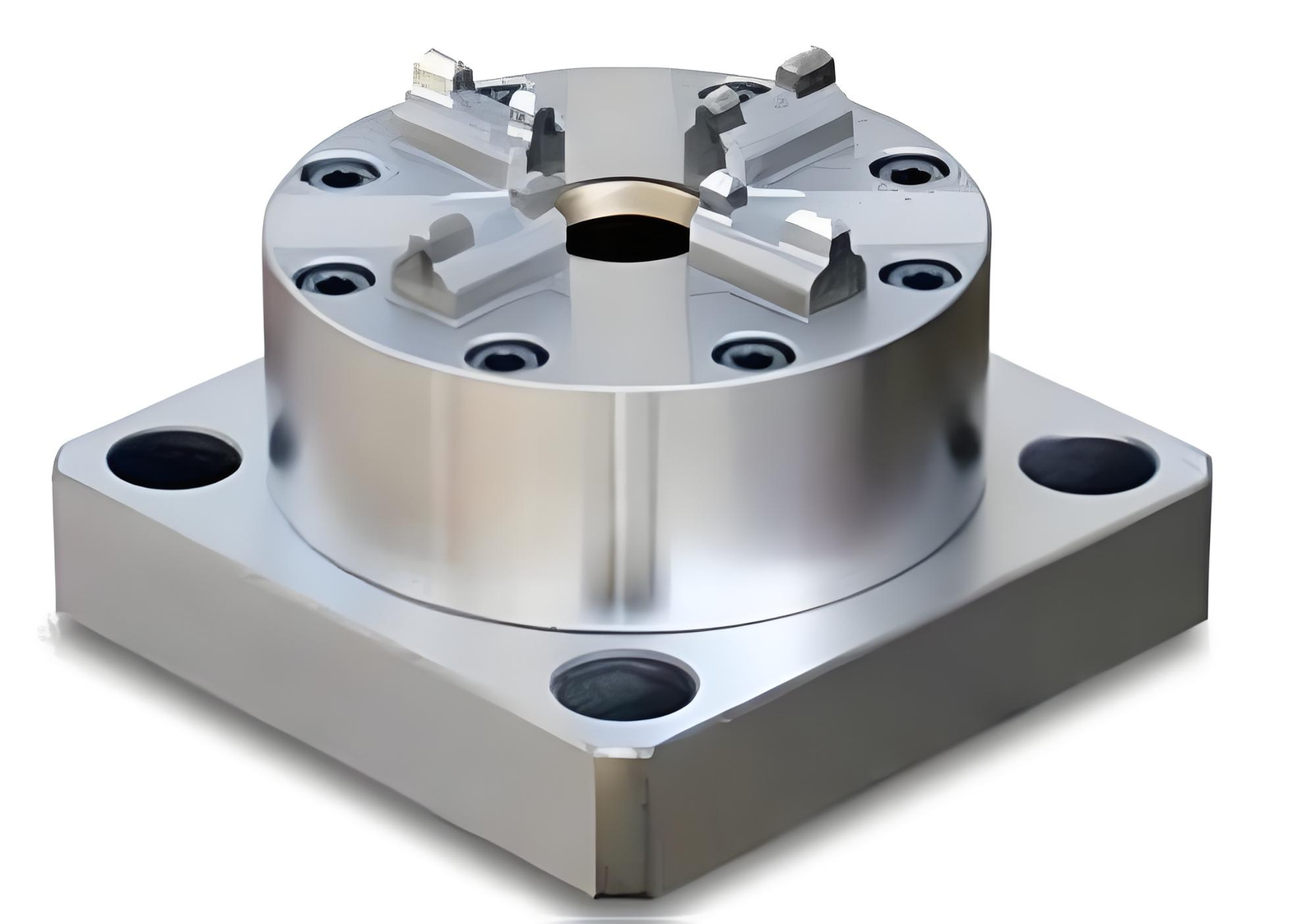

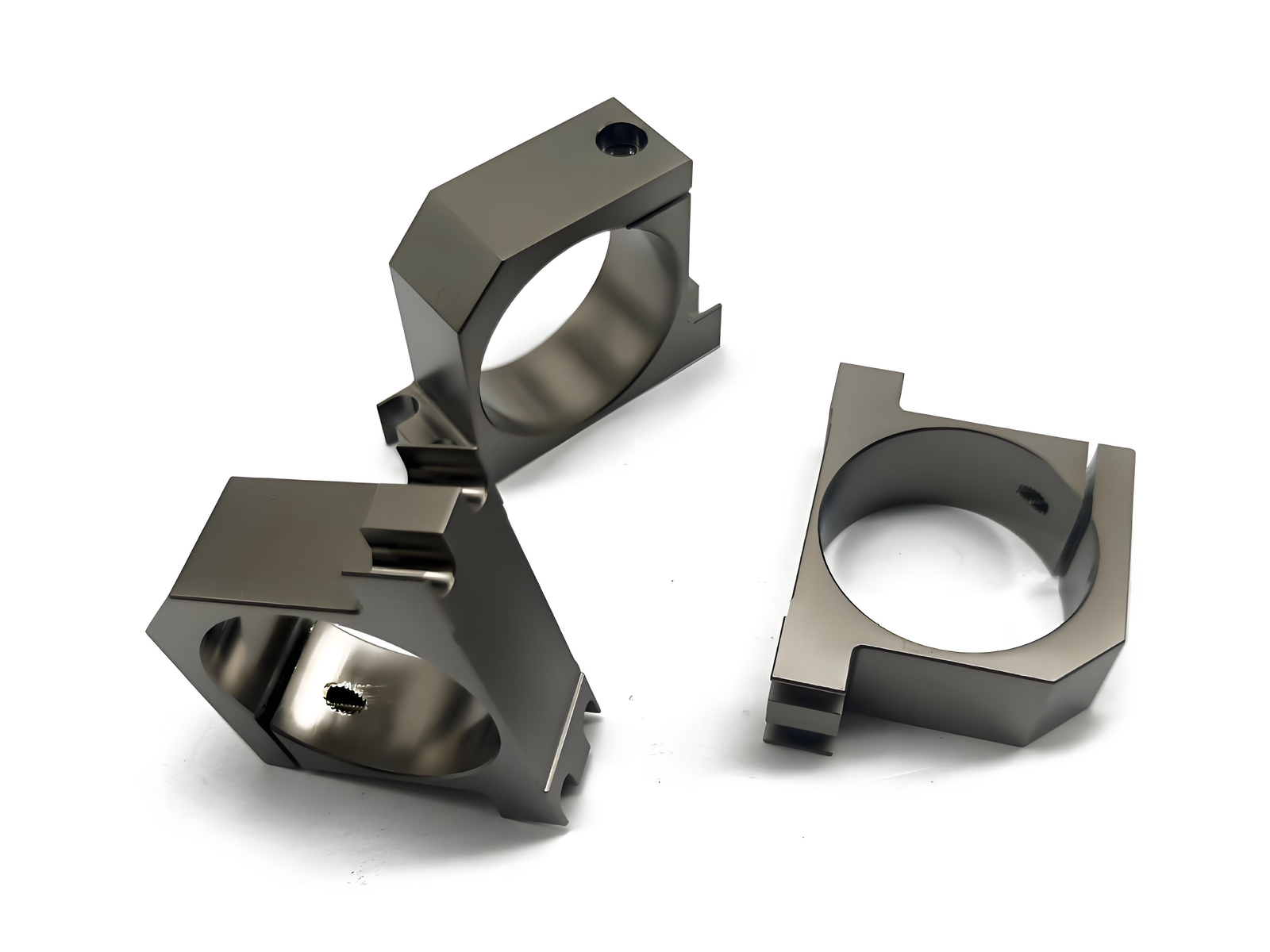

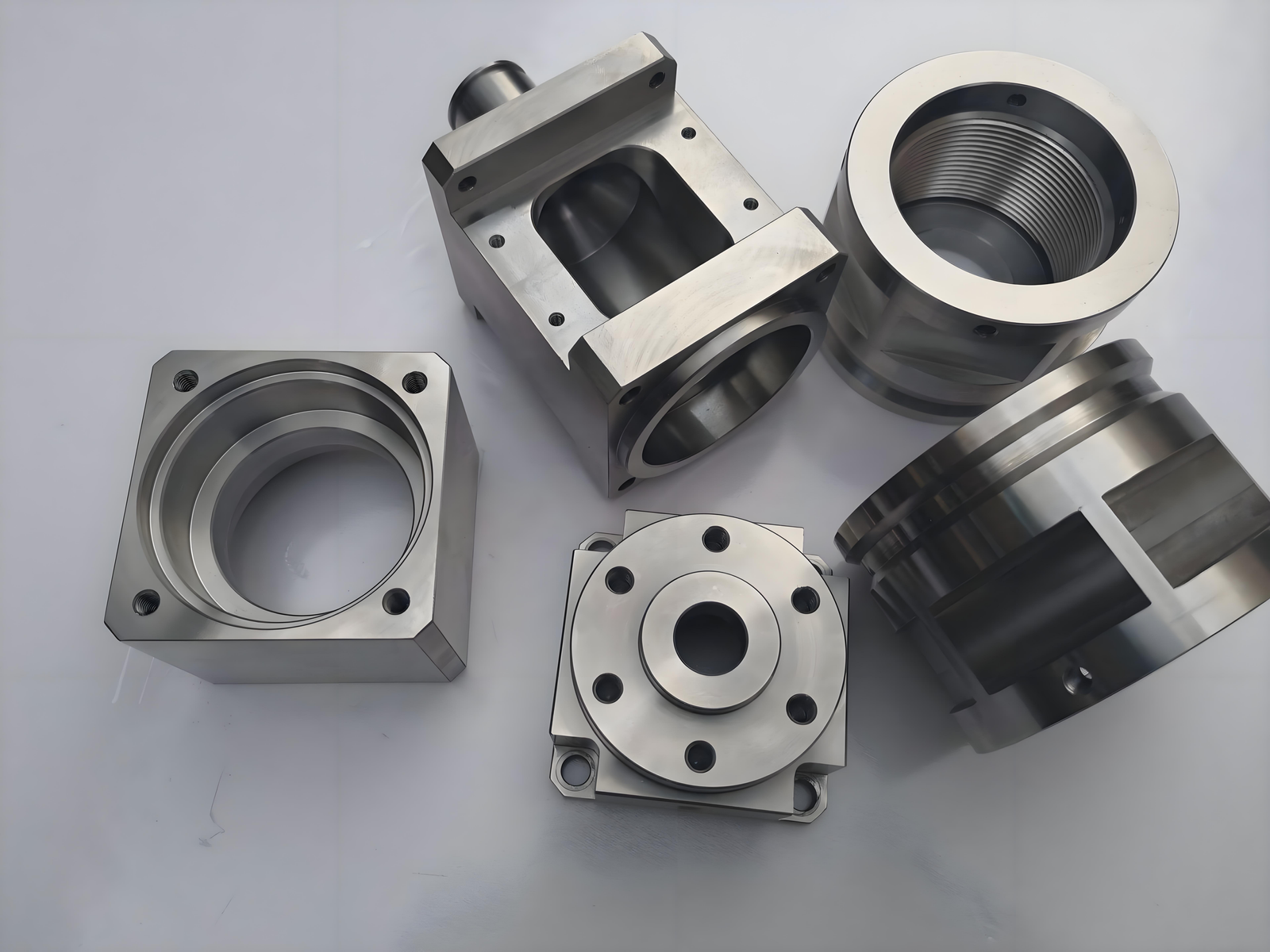

JUPAICNC focuses on providing high-precision and high-reliability core component processing services for the robotics and automation industries. We have advanced five-axis CNC machining centers, precision testing equipment and mature process systems, which can efficiently process difficult components such as robotic arm joints, servo motor housings, harmonic reducers, etc., with an accuracy of ±0.01mm, ensuring the stable performance of the product under high-speed motion and long-term loads. At the same time, we provide one-stop solutions from design optimization, material selection to batch manufacturing, supporting customization of various materials such as titanium alloys, aluminum alloys, engineering plastics, etc., to meet the diverse needs of collaborative robots, industrial automation equipment and special robots. Choosing JUPAICNC means choosing an efficient, precise and reliable manufacturing partner to empower your robotics and automation technology innovation!

Lightweight, high rigidity, corrosion resistance, suitable for mechanical arm structural parts and shells, balancing strength and weight.

High strength and corrosion resistance, suitable for food and medical robots, meeting clean environment requirements.

Ultra-high strength, high temperature resistance and good biocompatibility, used for key components of aviation and medical robots

Wear-resistant, self-lubricating, insulating, suitable for light-loaded gears, joint bushings, reducing noise, but limited temperature resistance.

Extremely lightweight, high strength, used for drones, bionic robot structural parts.

High strength (2~3 times of carbon fiber), high temperature resistance (1500℃), suitable for high temperature protection materials and lightweight structural parts

Enhance wear resistance and corrosion resistance, provide a variety of color options, suitable for robot arm housing and structural parts, improve aesthetics and functionality.

Ultra-high hardness (HV800+), wear resistance, suitable for high-load guide rails, joint parts, and extend service life.

Uniform coating, corrosion resistance and no risk of hydrogen embrittlement, suitable for precision gears, hydraulic parts, and ensure dimensional stability.

Eliminate reflections, improve surface texture, used for collaborative robot housing, and has both anti-fingerprint and industrial beauty.

Ultra-hard, low-friction coating, suitable for high-speed transmission parts, with both decorative and performance improvement.

Robot arm joint parts: high-precision five-axis machining is adopted to ensure ±0.01mm tolerance, achieve smooth movement and precise positioning.

Harmonic reducer housing: aviation-grade aluminum alloy one-piece molding, lightweight design and high torque transmission stability.

Servo motor end cover: precision heat dissipation gear structure optimization, effective control of temperature rise, and extended motor service life

Linear guide slider: hard anodized, friction coefficient as low as 0.001, to ensure long-term operation accuracy.

Robot end effector: Robot end effector: modular design, support fast replacement of fixtures, adapt to multiple scenarios such as grasping and welding.

Rotary encoder code disc: ultra-thin stainless steel precision etching, resolution of 0.001°, to meet high-precision closed-loop control.

Force sensor housing: magnesium alloy CNC processing, excellent electromagnetic shielding performance, to ensure signal transmission stability.

Collaborative robot carbon fiber arm: T800 grade carbon fiber composite processing, 5 times stronger than steel, 60% lighter.

AGV drive wheel assembly: polyurethane coated wheel hub, silent coefficient <45dB, suitable for more than 100,000 cycles.

Automated sorting mechanical claw: bionic structure design, gripping force 0.1-50N adjustable, response time <0.1s. Industrial robot base: cast iron stress relief treatment, vibration attenuation rate 90%, to ensure system stability.

Send drawings and detailed requirements va Email: info@jupaicnc.com Or Fill Out The Contact Form Below.

All uploads are secure and confidential.

The first article under $200 is free.( Background investigation required.)

At present, the automatic quotation of CNC is for reference only, and the actual discount is subject to manualcalculation. After submitting the inguiry, a professional customer service will communicate with you within 12 hours.

Best CNC Machined Parts Manufacturer and Factory in China.

Offer Fast and Cost-Effective One-Stop CNC Machining Services.